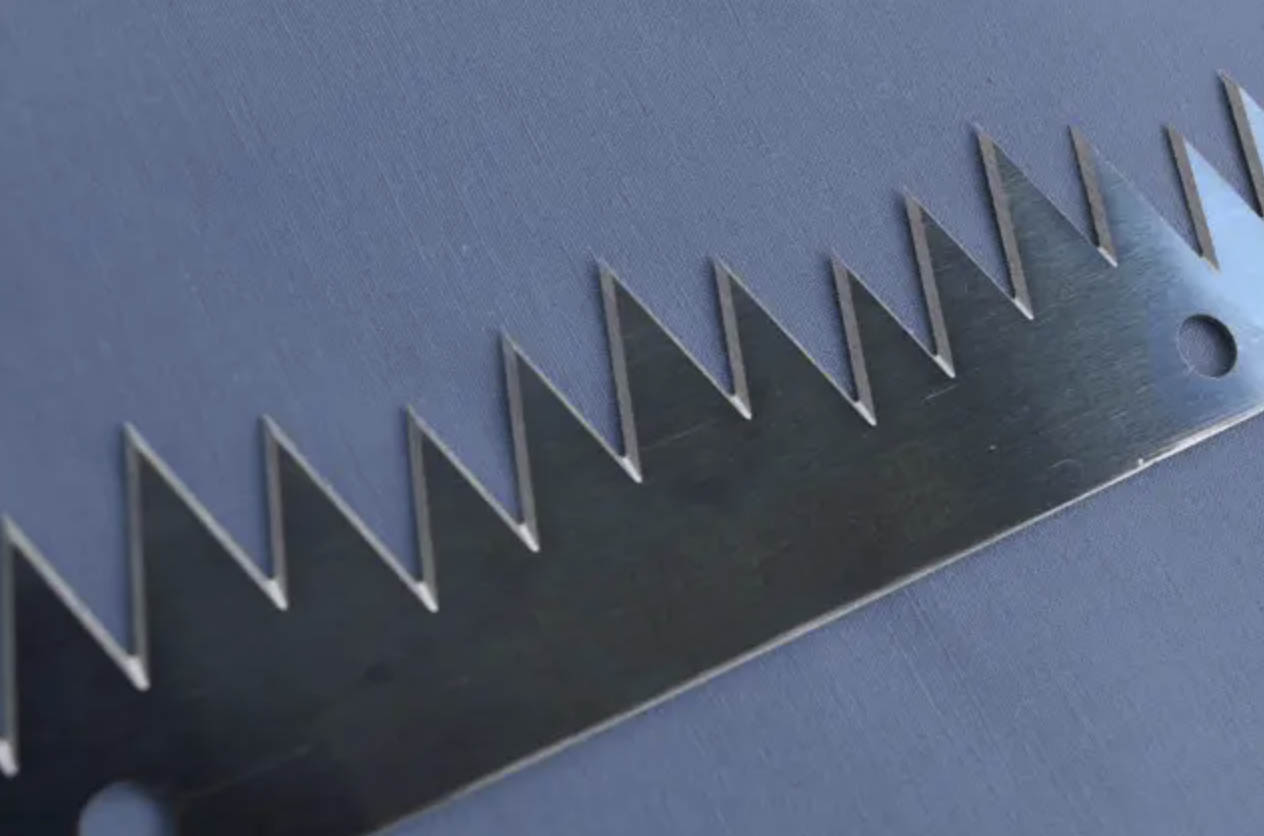

precision. accuracy. durability

Manufactured From the Finest Materials

Whether your industrial application involves shearing/cutting, chopping, perforating, folding, scraping, sealing, or slicing, you need an industrial blade designed with precision, accuracy, and durability in mind.

At Leverwood Knife Works, we understand the demands of industrial manufacturing from food processing and printing to paper cutting, packaging and converting. Our in-house team of experts utilize the latest in CAD technology and work seamlessly with your staff to identify your needs and develop the best solution for your particular application.

All of our machine knives are manufactured utilizing the finest materials available to ensure consistent dimensional accuracy and exceptional blade life and durability.

From standard blades to custom solutions, we work with a wide variety of industries to bring you the quality you demand at the most competitive pricing.

blade applications

Industries We Work With

See the difference our blades can make in your business.

Converting Knives

Whether you are converting paper, foil, or film, Leverwood Knife Works has the blades you need for the precision cuts you require. We manufacture OEM and custom blades to meet your unique cutting challenges.

Food Processing

From dairy and baking to confectionary and snack foods, we offer a wide range of food processor blades.

Flexible Packaging Blades

Available in straight, V-tooth, scalloped toothed, serrated tooth, zig zag, knife and anvil sets, or just about any custom shape, our packaging blades can handle your packaging specifications with ease.

Medical Packaging Blades

You need clean, precise cuts that work to keep packaged materials sealed, sterile, and up to medical-grade standards. Our team of experts is exceptionally experienced in understanding your need for packaging solutions. Let us help you make a cleaner cut.

Non-Woven Blades

Non-woven materials represent a unique class of textiles distinguished by how they are produced—instead of the customary weaving or knitting of fibers, non-woven fabrics intertwine fibers directly, using synthetic or natural fibers, or even a blend of both, tailored to the requirements of specific applications.

Paper Cutting Blades

Available in straight, curved, convex, toothed, or scalloped shapes, each paper cutter blade we manufacture is created with the highest grade tool steels to meet OEM specifications.

Profile, Extrusion & Tube Cut-off

All our cut-off blades are ground “Leverwood-sharp” to provide the cleanest cuts with the least deflection in the cut. Includes blades for plastic extrusion cut-off, guillotine cutters or shears, rotary tube cut-off, and blow-molding cut-off.

Printing Blades

Our printing industry knives are designed to perform in demanding production environments, providing consistent performance on both foreign and domestic equipment.

25+ years of industry expertise

Helping Meet Your Needs

Whether you are looking for a specific cut pattern, a longer lasting blade, or require a brand new blade for your equipment, Leverwood Knife Works has just what you need. A Leverwood sales professional will guide you through the process of selecting the blade characteristics that will best meet your production and quality requirements. All Leverwood Knife Works blades are custom manufactured to your exact specifications in our Red Lion, PA facility giving us full control of your blade from start to finish.

-

V-Tooth

-

Tear-Tab

-

Splitter Blades

-

Hi Low Tooth

-

Band Knives

-

Hole Punch

-

Stab Knives

-

Tapered Knives

-

Scraper Blades

-

Formed Blades

-

Bag Knives

-

Chopper Blades

-

Notching Blades

-

Diaper Blades

-

Perforating Blades

-

Vari-Tooth

-

Tissue Blades

-

Slanted Tooth

-

Multi-tooth

-

Back Beveled

-

Seal Bar Blades

-

Radius Knives

-

Front Beveled

-

Wrapper Knives

-

Circular – Straight

-

Thin Rimmed

-

Winder / Re-winder Blades

-

Circular – Toothed

-

Scalloped Tooth

-

Scoring Blades

-

Rotary

-

Wavy Edge

-

Tucker Blades

-

Stationary

-

Doctor Blades

-

Anvils

-

Extruder Blades

-

Folder Blades

-

Form/Fill/Seal

Ready to Get Started?

Call now at (717) 246-4105 to speak with a member of the Leverwood sales team to analyze your project requirements or click the link below and fill out the quick contact form to get started with your free quote. A Leverwood team member will contact you within 24 hours.