At Leverwood, our industrial food processing knives ensure quality and the best possible efficiency for your business.

For over 25 years, Leverwood has been providing the food processing industry with the cutting blades they need. Whether you are in the dairy, baking, confectionery, snack food, or any other food industry, Leverwood Knife Works is there to make the cut. We can manufacture the industrial food processing blades you need for your processing applications and packaging lines.

we’ve got you covered

Custom Food Processing Blades We Can Manufacture

We manufacture blades for various industries including:

- Poultry

- Seafood

- Meat

- Dairy

- Dough

- Fruit

- Vegetable

- Grain

Leverwood uses only the highest grade stainless steel products to manufacture food processing blades. As a result, our knives will hold up under the toughest abrasive and harshest corrosive conditions, as well as withstand washdown environments. Leverwood blades will not only get the job done efficiently, but we’ll also extend the life of your knife. That means cost savings to you in both blade replacement as well as machine downtime.

Over the past 25 years, Leverwood’s experience has helped us to ensure we exceed your needs and expectations on all of your standard, custom, and unique cutting requirements. Our blades and food processing knives can be found in most processing operations where superior blades are required. We manufacture blades for various industries, including poultry, seafood, meat, dairy, dough, fruit, vegetable, and grain. Even if you don’t see your industry listed here, we’re sure that Leverwood can provide the exact food packaging blade you need.

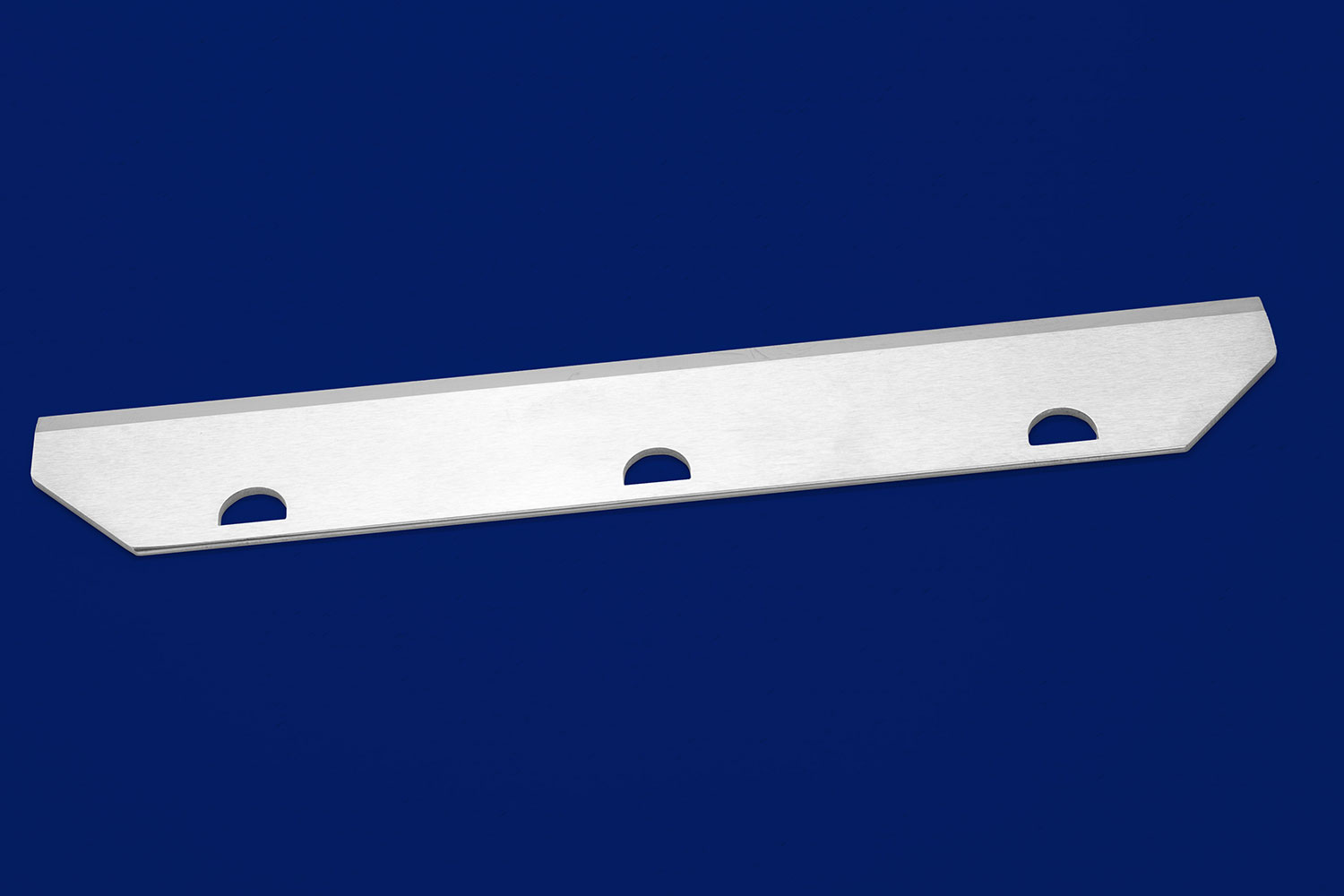

Scraper Blades

Our top-quality scraper blades are perfect for scraping out pans, bowls, or food products off of rollers and conveyor lines. These straight blades can also ensure a smooth scrape across your conveyor to remove products swiftly and without damage.

Extrusion Blades

When you have a food product like pretzels, dough, snacks, and pet foods that are extruded, you can rely on our extrusion blades. These blades slice off your product cleanly and accurately every time.

Dicing Blades

When it comes to dicing blades, you’ll want the highest-quality, sharpest blade possible to avoid any hiccups in dicing food products like fruits and vegetables, or during meat processing.

Serrated Knives

Our high-speed serrated knives are perfect for cutting through some of your thicker food products, especially for meat processing. The best part? Using Leverwood cutting blades means you won’t have to replace your blades nearly as often!

Guillotine Blades

Industrial food processing knives come in many shapes and sizes. So when you have large products that need cut to size quickly and efficiently, Leverwood guillotine blades (sometimes called chopping blades) may be precisely what you need.

Skinner Blades

When it comes to skinner blades, you’ll want the highest-quality, sharpest blade possible to avoid any hiccups in meat-processing. Let our Leverwood blades speed up your process and help reduce lead times!

Spiral Ham Knives

Specialty blades can be difficult to come by, which is why we take the time to fill that need. Our spiral ham knives are made to last, keeping your business running efficiently even during the busiest times of the year.

Poultry Blades

No matter which part of the poultry processing or packaging stage you’re working on, blades are always required. Our poultry blades will help reduce waste with cleaner cuts, keeping your process consistent and efficient.

25+ years of industry experience

Why Choose Leverwood Blades?

Whether you need a cutting blade manufactured to OEM standards or you have a custom and unique cutting challenge, Leverwood is here to help. Our years of experience as a leading industrial food processing blade manufacturer ensures that you are getting the highest quality blades on the market for any food processing production application.

Leverwood’s knives and blades will not only exceed your food cutting and processing expectations, but because of our high-quality materials—such as high carbon steels, stainless steels, and powdered metals—and state-of-the-art manufacturing processes utilized, you’ll likely see an increase in blade life. That means cost savings to you in both blade replacement as well as machine downtime.