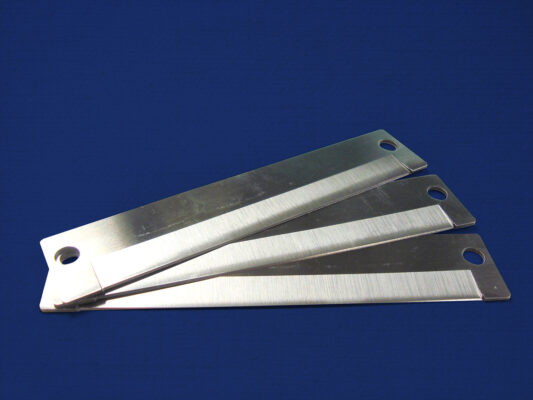

In the fast-paced world of healthcare manufacturing, where sterile integrity and precision are non-negotiable, custom medical packaging blades play a vital role behind the scenes. While “sharps” are specifically used in medical procedures, the precision-engineered blades used in packaging ensure the safe and secure delivery of life-saving equipment, medications and diagnostic tools. Whether it’s sealing blister packs of prescription pills or slicing sterile wraps for surgical kits, these blades are designed to meet the exacting standards that modern healthcare requires.

At Leverwood Knife Works, we recognize the vital role that industrial cutting tools play in maintaining safety and consistency across the medical supply chain. Whether it’s sealing a blister pack of prescription pills or slicing sterile wraps for surgical kits, our blades are designed with the precision that modern medicine demands.

Precision Cutting for PPE Packaging: Safety Starts with the Seal

The COVID-19 pandemic put unprecedented pressure on the supply of personal protective equipment (PPE). As millions of masks, gloves, and gowns were distributed globally, one thing became clear: packaging failures could be just as dangerous as supply shortages.

Blades used in PPE packaging must navigate tough materials, including Tyvek®, polyethylene, and composite films, without dulling or tearing. Our durable medical blades are designed to make crisp, uniform cuts—even under continuous, high-speed production conditions.

According to the U.S. Occupational Safety and Health Administration (OSHA), PPE packaging plays a crucial role in limiting exposure to pathogens, especially in frontline settings. That’s why our PPE packaging blades are engineered for performance under pressure—ensuring protective gear arrives sterile, intact, and ready for use.

In addition, as automation in PPE manufacturing continues to grow, the need for custom blades that can consistently perform in robotic and semi-automated packaging environments is critical. Leverwood designs each sharp to seamlessly work with high-output machinery, ensuring reliable performance with every cycle.

Pharmaceutical Packaging Blades:

Where Compliance Meets Precision

When it comes to medication packaging, the stakes are incredibly high. Whether you’re sealing sachets, strip packs, or unit-dose blister packs, every cut must be clean, accurate, and reliable.

Even a slight inconsistency in a packaging seal can affect medication shelf life, lead to compliance issues, or create patient safety risks. That’s why we design pharmaceutical packaging blades with exacting tolerances and materials that reduce wear, friction, and contamination risk.

The U.S. Food and Drug Administration (FDA) outlines strict guidelines for packaging integrity—underscoring the need for cutting tools that uphold performance batch after batch. At Leverwood, our precision-engineered blades help pharmaceutical manufacturers meet these benchmarks, while minimizing material waste and downtime.

Pharmaceutical packaging also often requires flexibility. As drug delivery systems evolve to include child-resistant, senior-friendly, and tamper-evident features, packaging becomes more complex. Our custom blade solutions are tailored to meet these evolving needs, ensuring that form never compromises function.

Sterile Packaging for Instruments, Diagnostics, and Implants

The rise of minimally invasive procedures, at-home diagnostics, and biologic therapies has expanded the need for sterile packaging solutions. Whether it’s a surgical instrument, a rapid diagnostic test, or a prosthetic implant, the packaging must remain sealed—yet be easy to open in critical moments.

Our custom medical blades are designed to preserve sterility and usability across a range of materials, including medical-grade foils, multi-layer films, and specialty wraps. Each blade is crafted to make clean, precise cuts that reduce particulate contamination and preserve packaging integrity.

The World Health Organization (WHO) highlights sterile packaging as a pillar of infection control. Our sterile packaging blades help customers maintain those standards—supporting better patient outcomes from factory floor to operating room.

What sets Leverwood apart is our dedication to supporting both high-volume and niche applications. Whether you’re packaging thousands of surgical kits per hour or developing a new line of diagnostics for home use, our blades are engineered to deliver.

Blades That Serve Beyond Healthcare

Although we’re known for our work in the medical field, our expertise extends to other sectors where high-precision cutting tools are essential. From food-grade packaging to cleanroom manufacturing, our customers rely on our blades for their versatility, consistency, and long-term value.

We design every industrial knife with application-specific performance in mind—considering everything from coating options and edge angles to material compatibility and automation requirements. Our collaborative design process means each blade is not just a tool—but a tailored solution.

And as sustainability becomes a greater focus, especially in healthcare, our team works on solutions that help reduce waste and enable cleaner cuts on recyclable and biodegradable materials. From eco-friendly pharmaceutical packaging to zero-waste PPE kits, our blades make precision possible.

Why the Right Blades Matter More Than Ever

Today’s medical packaging isn’t just about sealing a product—it’s about enabling traceability, ensuring sterility, and improving the user experience. With growing demand for sustainable materials, smart packaging, and global distribution, packaging lines face increasing complexity.

A recent National Institutes of Health (NIH) study emphasized how tamper-evident and contamination-resistant packaging directly impacts supply chain integrity in medical settings. Without the right custom cutting solution, even the most advanced packaging system can fall short.

At Leverwood, we stay ahead of these trends by continuously investing in innovation—from blade coatings that extend lifespan to custom geometries that improve speed and accuracy. We’re not just supplying tools—we’re supporting the evolution of healthcare manufacturing.

We also offer guidance on material pairings, production line integration, and long-term cost efficiency—because choosing the right blade is about more than specs. It’s about optimizing your entire process.

Cutting Ahead: The Leverwood Advantage

Our commitment to quality isn’t just in our products—it’s in our partnerships. We work with OEMs, automation engineers, and packaging specialists to develop solutions that fit their equipment, workflows, and goals.

Whether you need pill packaging blades, PPE packaging knives, or specialized industrial blades, we deliver blades that help you meet your production targets and quality standards—time and time again.

As we look ahead, Leverwood is committed to staying at the forefront of blade technology, offering innovative solutions to meet the evolving needs of healthcare and pharmaceutical industries. From biologic packaging to smart label applications, our blades are ready to cut through the challenges of tomorrow.

Explore how Leverwood Knife Works is shaping the future of medical packaging: Medical Packaging Blades by Leverwood

From PPE to pharmaceuticals and everything in between, custom blades aren’t just a component—they’re a critical part of the process. With decades of experience, cutting-edge technology, and a commitment to quality, Leverwood is proud to help shape the future of medical packaging—one blade at a time.