As a manufacturer that creates machinery for other manufacturers, you know that your products have to be top-of-the-line to be competitive. With so many industries using your machinery, you need to make sure every detail is perfect—right down to the type of blades you use. For example, if you produce tray sealing machines, you’ll want to make sure you have the right tray sealing knives in your packaging equipment—this attention to detail can mean all the difference to your clients.

Like most businesses, you want clients to think of your products as the best in the industry. At Leverwood Knife Works, we understand that “good” isn’t always “good enough,” which is why we always strive to be a cut above the rest. When you use our blades, not only are you investing in premium quality, you’re making sure your customer base is satisfied.

In this article, we want to help educate you and your clients about tray sealing knives and why their quality truly matters in production lines.

What are Tray Sealing Knives?

If you’re not yet familiar with tray sealing blades or what tray or cup sealing entails, don’t worry—it’s a pretty simple concept to grasp.

If you’re not yet familiar with tray sealing blades or what tray or cup sealing entails, don’t worry—it’s a pretty simple concept to grasp.

First, look around you—is there a microwavable lunch container sitting near you, or maybe a cup of yogurt left over from breakfast this morning? Both of these products have likely gone through a food tray sealing machine.

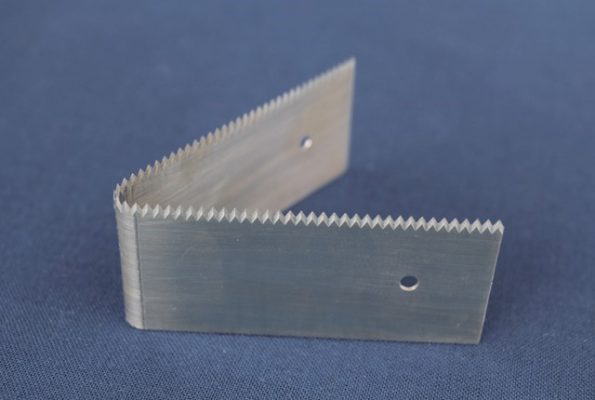

The protective plastic film that you see over most food products is placed there using tray sealing machines. The product—or tray—runs through a machine, and a specialized blade comes down and trims the material around the tray. This is where Leverwood comes in.

Every blade that Leverwood makes is customized to fit the specifications that you, the manufacturer, give us. While most of the time there are standard trays and sizes, we know that each blade may require design changes depending on the product and type of material that is used.

Common Tray Sealing Blade Applications

Tray sealing knives vary quite a lot. From material to coating, blade makers like us will customize knives for an individual company and the sealing standard in specific industries.

For example, some products (possibly in the food industry) require a film with special backing, which can completely change the blade configuration. Every customer is different, and Leverwood works to accommodate every industry that we can.

A few common tray sealing blade applications include TV dinners, yogurt (for cup sealing), medical packaging, and much more.

Blade Customization

With so many standard applications of tray sealing knives, each client will likely want their own specific type of customization. For instance, if your client wants a straight edge cut on their products, they should go with a scalloped-edge blade.

Maybe one of your customers wants a tighter packaging seal, so there are more teeth on the blade (which can change the appearance of the edge). No matter the configuration required, Leverwood will work with you to manufacture precisely to your specifications. Here are a few typical applications and industries that we tend to work with:

- Food Processing

- Fruit & Vegetable Processing

- Paper Cutting Blades

- Packaging Blades

- Printing Knives

- Plastic Cutting Blades

- Converting Knives

How Leverwood Blades Can Help

When you use Leverwood blades for your tray sealing machine, you’ll have peace of mind knowing that your products are using the best blades in the industry. Not only will this help your business, but it will help your clients cut costs by reducing machine downtime due to faulty blades.

Here at Leverwood, we strive to always be a cut above the rest in our industry. This is why everything we make is custom and manufactured to your exact specifications. The best part? All of our products are made in-house right in Red Lion, Pa., so there’s no overseas costs or wait times.

If you’re ready to give your clients the perfect cut that they expect with their machines, reach out to us today. We’re here for all of your custom blade solutions.